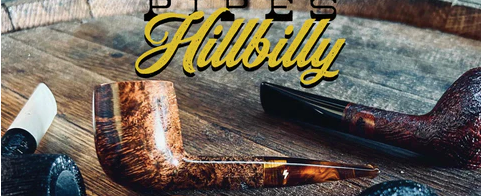

Explaining the Notch

With a few exceptions, the drilling in pipes are a series of connected, straight holes whether the pipe is straight or bent. This can pose some challenges in pipes that are significantly bent. The obvious necessity of making sure that the airway stays on the inside of the pipe and connects to the tobacco chamber paired with aesthetic ideals usually requires that the airway and mortise be drilled on different axes. Conventional wisdom in pipe engineering also says that the airway in the stem and in the bowl should line up where they meet in the bottom of the mortise for better airflow from chamber to smoker. There are differing theories on how best to overcome these challenges but today we are going to discuss one particular approach as we employ this technique on some BriarWorks and Moonshine pipes and have been asked about it numerous times.

The solution that we use to accomplish these goals is to drill a notch on the bottom side of the mortise. This notch isn't visible while the stem is on, but it is clearly visible on the shank face when the stem is removed. For those not familiar with this method it can be a bit of a surprise. A surprise whose purpose is not always immediately obvious. For those seeing these types of notches for the first time on a BriarWorks or Moonshine pipe, rest assured, it is intentional and designed to provide a better smoking experience. These photos should help illustrate further.